Leadership Through Quality

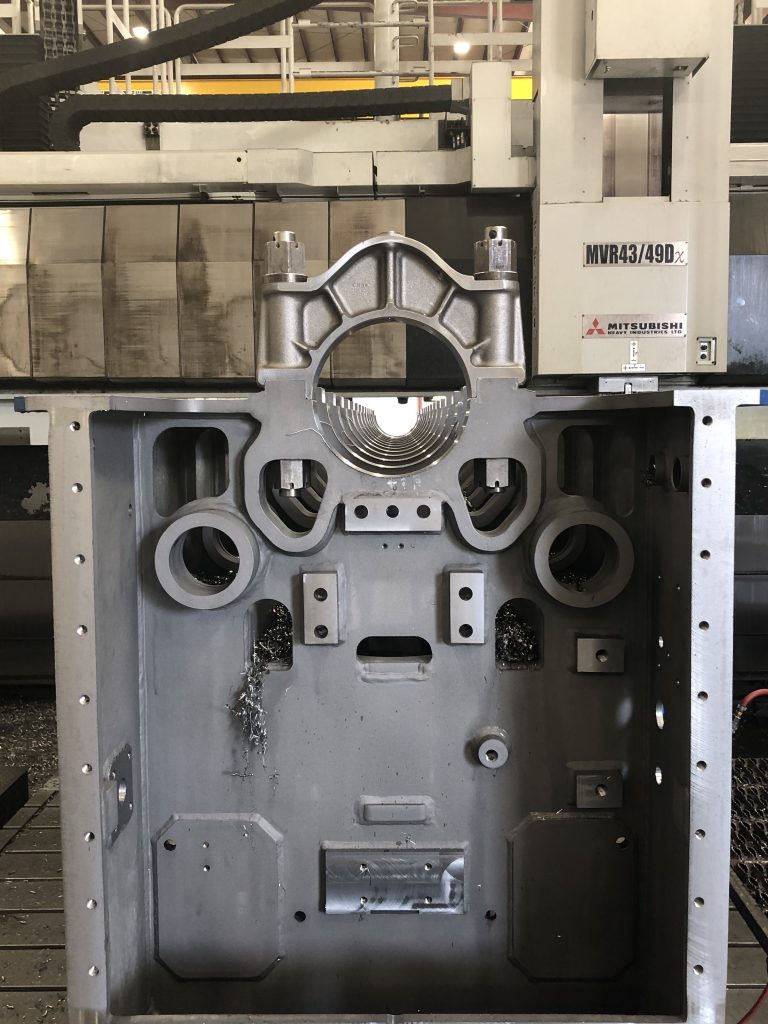

Machining

K&M’s flexible machine shop is production oriented, with up to 50 ton crane capacity to handle your large machining needs. We have 25 Plus state-of-the-art Horizontal and Vertical CNC machines with the latest technology and multiple spindle attachments.

Fabrication

K&M’s fabrication shop offers multiple robotic welding cells complemented by certified welding specialists trained in a variety of techniques. Large fabrications are our specialty. AWS qualified welders and AWS Certified Welding Inspectors on staff.

See Fabrication Equipment List

Inspection

K&M’s inspection capabilities include a large CMM and a Faro Laser Tracker.

Burning

K&M’s in-house burn shop offers a multiple head plasma and a laser burning table that can handle a broad range of plate sizes and thicknesses.

Assembly

K&M offers cost-effective electrical, hydraulic, and mechanical assembly services.

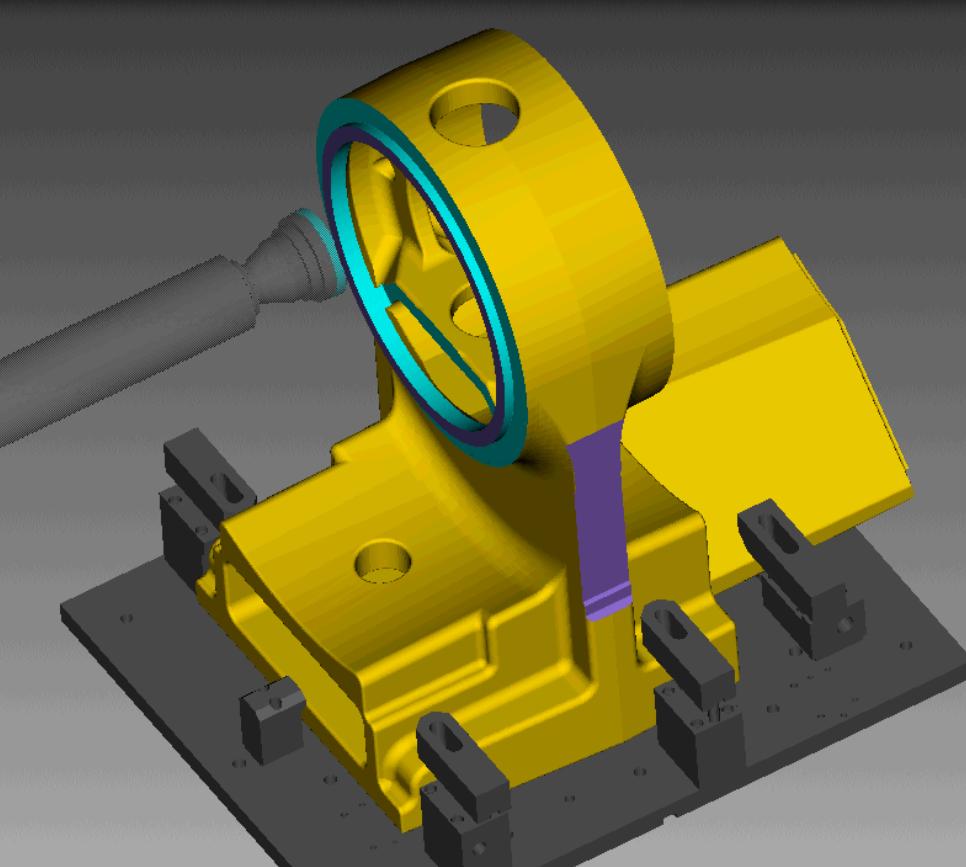

Engineering

K&M’s engineering provides fast quote turnaround, design for manufacturability evaluation, tool design, project management, control plan, PFMEA , and fixture design and build . K&M engineering is experienced in the latest tooling, welding, and machining processes. This experience is applied to our customers’ products to provide a cost effective and high quality manufacturing process.

Sculpture Fabrication

K&M’s nationally recognized Sculpture Fabrication Division provides a useful resource for artists that work with large scale metal designs.